Download the technical specification of this LEV enclosure with sliding sash using the following button. Alternatively, watch the video below for more details. If you are looking for a bespoke instrument safety enclosure, please contact us.

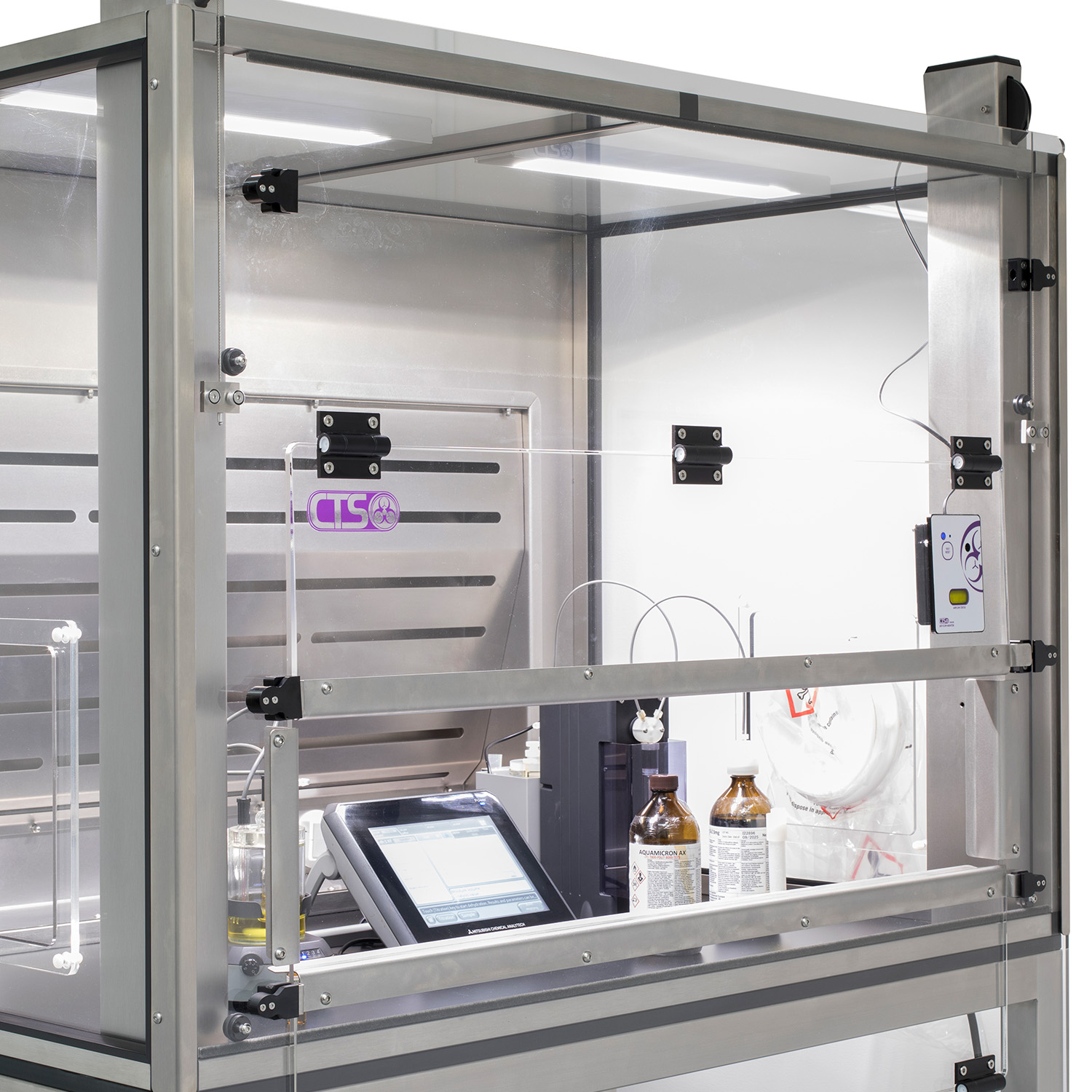

CONSTRUCTION

- Stainless steel skeletal frame

- 8mm Optically clear cast acrylic panels

- Black Phenolic resin base

- Stainless Steel Plenum

- Custom built Solutions

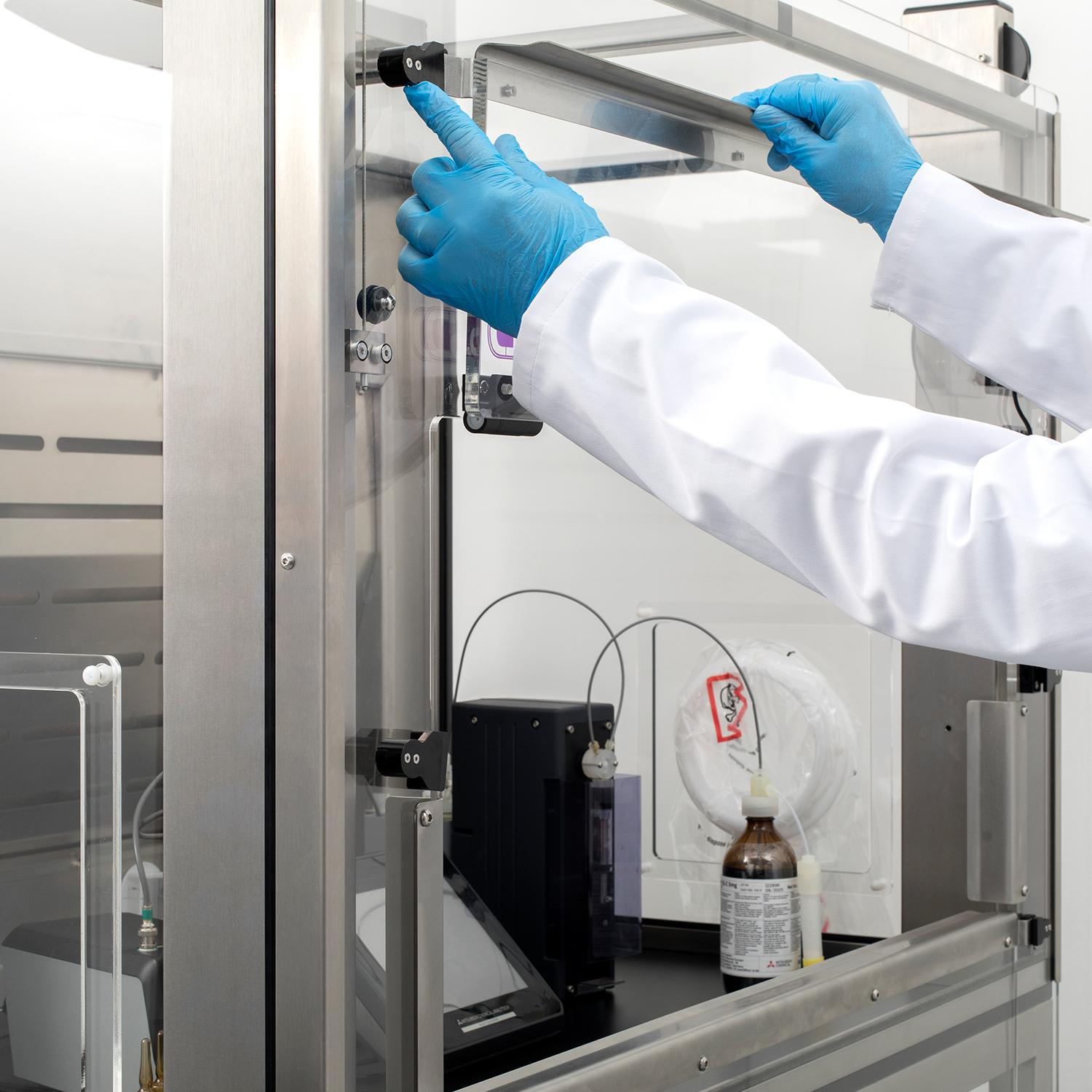

- Easy access for large equipment

- Bench Mounted or Free Standing

- LEV enclosures with Sliding sash are designed to customer specification

SYSTEM DESIGN

- Sliding Sash design allows easy access

- Constant air volume design provides

better containment - Surrogate tested for containment of APIs

- ECL Design to 0.1ug/m3

- Can operate as a stand-alone system or

be connected to the house extract system - Each system design is created and stored as a CAD file with CTS. Should a customer wish to change the functionality of their enclosure in the future, CTS can re-engineer a solution on site, with minimal disruption to othe laboratory.

POWER REQUIREMENT (SINGLE PHASE)

- 230v/50Hz/13A Service (EU)

- 110v/60Hz/20A Service (USA)

FACILITIES REQUIREMENT

- Re-circulatory design, can be stand-alone operation or connected direct to house

extract

FILTRATION

- Safe-change HEPA filter

- Modular air handling filtration unit

- Min 99.995% efficiency at 0.3 microns (H14)

- Activated Carbon filtration available

AIRFLOW MONITORING

- Continual airflow monitoring using a dual sensor hot wire anemometer complete with audible / visual alarm