Bespoke Laboratory Safety Enclosures

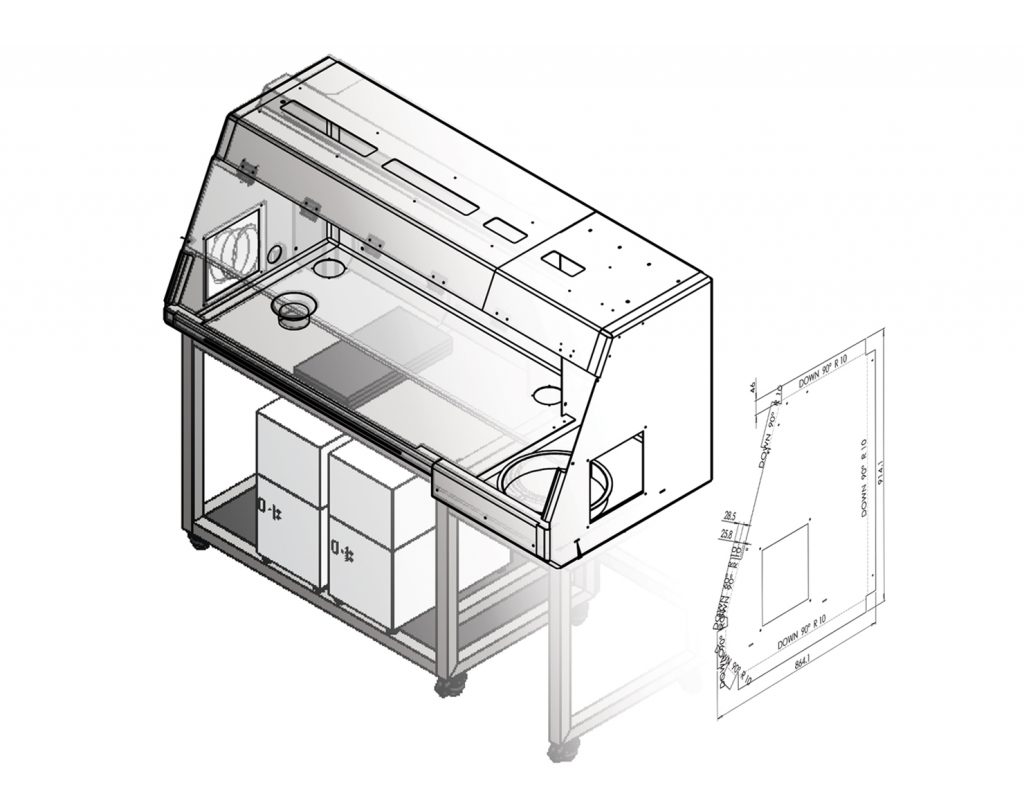

Bespoke laboratory safety enclosures are designed to each customer specification and can be manufactured from either acrylic or stainless steel and supplied either ready with air extraction and filtration units or for direct connection to an in-house extract system.

With an expert in-house engineering design team, consultative approach to design and purpose-built manufacturing facilities, CTS provide application specific laboratory containment systems dedicated to the safe use of a particular piece of equipment.

The design approach will take into account how the equipment is used, how it is serviced and how the operator can work with minimal contamination risk. Each system design is stored as a CAD file. With CTS, should the customer wish to change any dimension aspect of the enclosure, CTS can provide a built kit to add to the existing system.

Discuss your requirements

If you would like to discuss potential applications for containment, fill in the contact form below, call +44 2392 695521 or send an email tosales@containment-technology.co.uk

Bespoke Laboratory Safety Enclosures Portfolio

Browse CTS portfolio of bespoke systems and devices. Ranging from small portable devices to large scale laboratory enclosures. Custom systems include: Portable Containment Devices, Stainless Steel Solutions, Unique Environments and Laboratory Process Containment Systems.

Bespoke Project Phases

CTS provide end-to-end Laboratory containment system solutions.

Design Consultation

Following user and system requirements, CTS design engineering team reviews the safety aspects of the system applications and generates a design specification for client's consideration.

CAD Engineering

A 3D CAD model of the enclosure is created, enabling the client to modify dimension aspects of the system and to collaborate with the design engineering team to achieve the best possible solution.

Custom Manufacturing

All components are 100% made in the UK, and assembled and fitted at CTS facilities in Portsmouth. A quality control procedure (QC) is carried out to ensure that the system functions as expected once built.

Factory Acceptance Test

CTS can undertake FATs. The testing is performed during and after the assembly process to verify that the system is built and operating in accordance with the design specifications.

Service & Validation

IQOQ packages are provided as standard, ensuring all safety systems perform as expected. All CTS equipment is pre-qualified prior to shipment. CTS provide preventive maintenance and service support on a rolling basis.

Delivery & Installation

CTS offer delivery and installation of their laboratory safety systems in the UK and abroad. Worldwide coverage is possible through experienced channel partners in over 40 countries.

WINNER OF THE QUEEN'S AWARD FOR ENTERPRISE: INNOVATION 2019

contact form

If you’d like a free consultation, please start by completing the form: