Choosing a Laboratory Glove Box can be a complex process. Having a wide range of configurations at their disposal, technicians and operators are at liberty to choose a glove box befitting their specific requirements.

A glove box works either way, as it works to protect the contained content from environmental contamination or works to protect the operator from any hazardous material within. Hence, it is of paramount importance for operators to diligently choose the material, size and type of glove box they require.

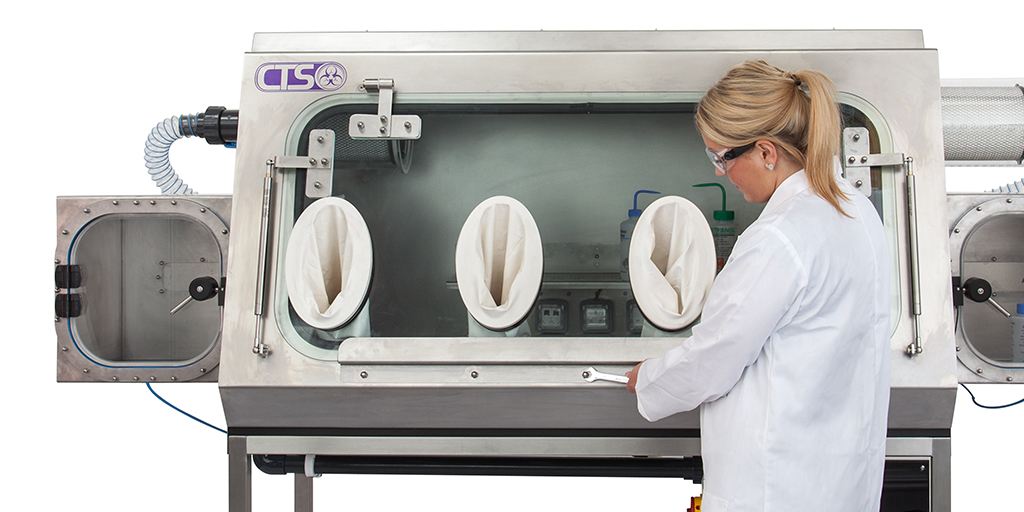

With each laboratory working on a different specimen, their requirements are unique. A glovebox is essentially a sealed container manufactured to allow the manipulation of objects within a controlled environment. Built into the sides of the container are gloves, which are located and arranged for the user to place their hands and execute tasks without breaching the isolation protocol. Be it materials such as toxic chemicals, radioactive material or biological materials (DNA or viruses) a glovebox works to provide controlled conditions, where the specimen stays unexposed to external environmental conditions, e.g. moisture or oxygen.

Types of Glove Boxes

- Basic Glove Boxes: Such boxes provide a draft-free environment paired with short-term protection for the contained specimen from the outside environment. Certain models are manufactured for the reduction of moisture and oxygen. They offer limited protection from volatile material to the user.

- Multi-hazard & Biohazard Glove Boxes: Designed to specifically protect the operator, this glove box works to protect the technician from biological hazards through the use of HEPA filtration and outside ventilation. Certain high-quality boxes also make use of inlet particulate filtration, precise pressure control for maximising operator safety and operational integrity, and a media for absorbing volatile organics.

- Controlled Atmosphere Glove Boxes: Such a box is manufactured to remove a high percentage of air for the protection of oxygen or moisture-sensitive material, usually using nitrogen or vacuum cycling. Certain boxes feature robust construction and material, which work to resist gas leakage and solvent attack.

Industry / Lab Requirements

Understanding how certain laboratories and industries require customised features, a laboratory glove box can be designed and manufactured to meet the lab’s specific requirements, they provide application specific solutions, be it involving the following elements:

- Instrumentation enclosures

- Climatically controlled enclosures

- Powder weighing enclosures

- Glove boxes and isolators

Glove Box Manufacturing Materials

Employing the use of a closed lens, it becomes apparent that the operators need to be aware of the following elements prior to choosing a glovebox, whether it is a pharmacy glove box. Fibreglass and stainless steel are more impermeable to moisture and oxygen when compared to other materials, such as vinyl, polycarbonate and acrylic. Entailing optimal stain resistance, moisture resistance, cleanability, chemical resistance, and heat resistance, they are a far better option than other permeable material.

It is equally important for operators to consider the sort of filtration they require, as depending upon their requirements, glove box manufacturers manufacture glove boxes.

- ULPA Filtration: This sort of filtration is optimised for particulate, chemical carcinogens, non-biohazardous microorganisms and nanoparticulates.

- HEPA Filtration: This sort of filtration is suitable for biochemistry, research and design and pharmaceuticals.

Having the fundamentals clear helps operators to choose an appropriate glove box, be it choosing a laminar flow glove box or an inert glove box.

If you need assistance regarding Glove Boxes or laboratory Containment, give us a call today on +44 (0)2392 695521 or write to sales@containment-technology.co.uk. At CTS Europe we provide a full system design service and are happy to discuss your containment requirements.